WELCOME TO

BITTER TOOLSHOP & STAMPED PARTS

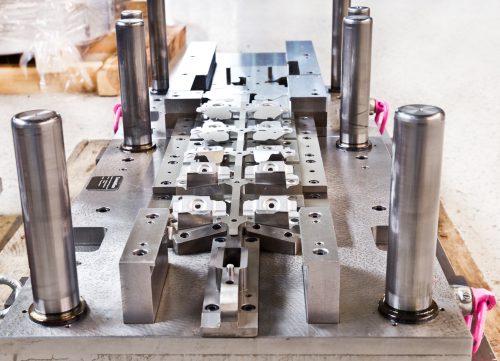

FROM PROTOTYPE TO SERIES

We are a family-owned company in its third generation that works with you to develop concepts from prototype to series with the highest quality solutions in toolmaking and stamping – fast, precise and highly productive!We offer key engineering, manufacturing and stamping services using state-of-the-art equipment. Our customers are located in Germany and abroad and come from the automotive, mechanical engineering, compressor construction, renewable energy, building services and electrical engineering sectors.

Tool design and construction of progressive dies

Assembly of modules

Stamping for high-volume and small-batch production from 35 to 400 t.

Manufacturing of prototypes and high-precision single parts

Please send your inquiries to:

anfragen@bittpro.de

Please send your applications to:

bewerbung@bittpro.de

Address:

Industriestraße 6

D – 96487 Dörfles-Esbach, Germany

Phone: +49 9561 795593-0

Fax: +49 9561 795593-9